Total Quality Improvement

In Strategic Solutions, we view quality as a management philosophy, not as a set of tools. Although tools are involved, management must drive the initiative if it is to succeed.

In Strategic Solutions, we view quality as a management philosophy, not as a set of tools. Although tools are involved, management must drive the initiative if it is to succeed.

Our approach is to build quality into the business and operating processes by taking out variability and/or non-value-added steps, depending upon the symptoms. This approach minimizes errors and greatly reduces the amount of steps, time and costs. Dollars fall to the bottom line, and it happens quickly.

Knowing that change is never easy, we focus on results, use appropriate tools, and just-in-time training. When variations in a process are causing problems, we use root cause analysis to produce more consistent results. When excessive time, lack of flexibility, high costs, or lack of successful process outcomes are creating undesirable results we will look to eliminate non-value added steps. At times we may create an entirely new process while in other times we eliminate redundancies and bottlenecks.

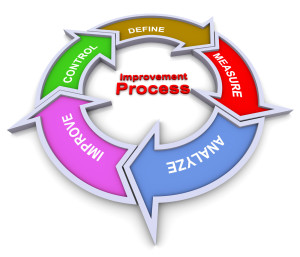

Our uniqueness lies in our implementation model:

This proven model focuses on aligning management and operating systems with strategic direction. After all, if your customers can’t see the difference, what has been achieved?

Results our clients have achieved include:

• Improved customer and employee loyalty

• Increased speed and accuracy

• Improved profitability

• Improved time to market with new products

• Improved market share

• Increased revenue

• Increased capacity and productivity

• Created continuous improvement and customer-focused growth

• Implement cycle-time reduction and process re-engineering

• Alignment of management and operating systems with strategic plan